The Rise of Digital Scales

As technology has advanced over recent years, the affordability and precision of digital scales has been greatly improved, contributing to their widespread usage. While there are many types of digital weighing scales, the most common ones are based on strain gauge technology. This is due to their high precision and low cost of manufacturing.

Strain Gauge Load Cells

Scales using strain gauge load cells work based on the principal of electrical resistance. To understand resistance, it is often useful to think of electricity as water flowing through a hose. As water passes through the hose, the flow can be restricted in many ways such as pinching the hose at one point. In a similar fashion, the flow of electrical current in a circuit can be restricted by decreasing the width of the conducting wire. One way to decrease the width of a wire is by stretching it like a rubber band.

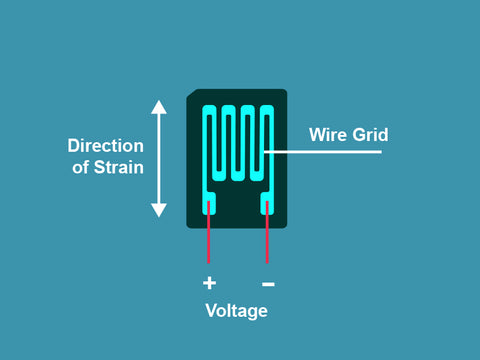

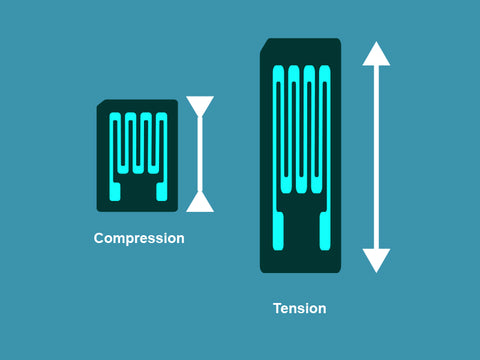

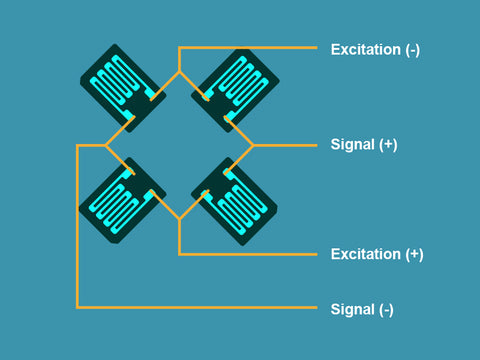

Strain gauges are composed of a strip of conducting wire arranged in a zig-zagging pattern that allows the wire to be stretched or compressed at several places along its length, maximizing the amount of deformation. The electrical current flowing through the load cell increases and decreases as the strain gauge is stretched and compressed. By reading the input and output voltage of the strain gauge circuit, stress can be measured. Strain gauges are used in many applications to measure the stress that a material undergoes during usage, like the hull of an airplane during aerodynamic testing.

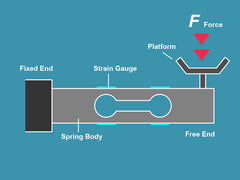

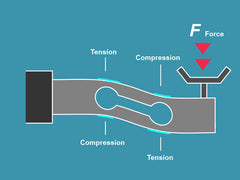

In a strain gauge load cell, the strain gauges are placed along a length of metal which forms a type of spring like a diving board. The spring body of the load cell often has holes cut into the side which intentionally weaken the spring and focus the strain to specific points. The strain gauges are placed directly above these weak points to measure maximum strain.

The scale’s platform is mounted to the load receiving end of the load cell, while the other end is fixed to the base of the scale. As weight is added to the platform, the load cell bends like a diving board with a person standing on the edge. This in turn causes the strain gauges to stretch and compress at the weak points, changing the resistance in load cell’s circuit. The changes in voltage, even at maximum capacity, are extremely small and require amplification to be made useful for measurement.

Calibration – From Electrical Signal to Digital Readings

But how does the scale measure weight using these voltage readings? This is where calibration comes into play. During calibration, the voltage readings from the load cell while nothing is on the platform (zero/neutral) and with max weight applied are converted to a digital value and stored in memory. This is why it is important to use accurate calibration weights when calibrating your scale. Because calibration uses a known mass value such as 500g for instance, the scale can determine the conversion factor necessary to scale the voltage reading into a weight reading.

The process of measuring the load cell’s voltage changes and converting them to a weight reading is not without its drawbacks though. Because the changes in voltage from the load cell are so small, they can be influenced by electrical “noise” from the surrounding environment, such as the electromagnetic waves generated by strong electrical devices and radio waves. Most scales have some degree of electromagnetic shielding to reduce these influences, but strong electromagnetic waves can still cause scale readings to fluctuate. It is important to keep cordless phones and routers away from your scale when in use. Even static electricity can cause problems for digital scales. To reduce static, you can use anti-static wipes and avoid extremely dry environments.